Metal objects are around us all day, every day from our morning cup of tea stirred with a metal spoon to us driving around in vehicles that are a conglomeration of metal parts. The manufacturing industry would not survive without its raw materials, metal spinning and welders, but have you ever wondered how sheet metals take on new shapes to become important parts, components or even finished products?

It is the art of metal fabrication that takes metals through an assembly process and transforms them into useful parts and components. This process involves many complex methods. Some of the most frequently used are:

Cutting

Metal is produced in large sheets, the cutting process it used to cut these sheets to the desired size for the required forming. Times have moved on from a saw and now many techniques are used which include the use of lasers, water jets, and plasma torches.

Shearing

When using shearing, one long, single cut is made on metal sheets to cut them to the correct size. It is, in fact, a very similar process to using a paper guillotine.

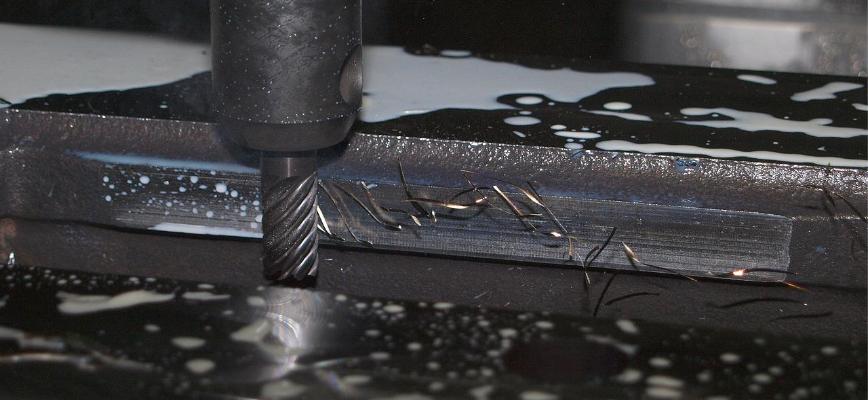

Machining

Machining is the process of removing metal and reshaping it into the end product using machinery such as drills, CNC metal spinning lathes.

Punching

As its name would suggest this process uses a punch and a die to make holes in the metal. With this process, it could be a sheet of metal with the holes or the pieces removed from it that can become the end product. Ideally, for lean manufacturing both would be used.

Stamping

This process creates a raised section by pressing it between a stamp die. It is similar to punching except that the material is not penetrated or cut.

Folding

If the metal needs to be bent or creased into shape, also known as folding, a brake press is used. It is a complicated procedure that can slow down the manufacturing process which can make it cost intensive. An alternative to folding is to fasten two different pieces together.

Welding

The welding process uses heat to join two pieces of metal together. Many different types of welding are used to meet the manufacturing requirements of the range of different metals.

So as you can see there are many types of metal fabrication and this is just a selection of the most common.

There are many more out of the ordinary fabrication processes that are used, particularly in lean manufacturing, and, of course, there are new methods under development all the time.

If you are interested in a career in metal fabrication the manufacturing industry is at the forefront of many apprenticeship schemes and so is ripe with career opportunity.

Be the first to comment on "What is Metal Fabrication?"